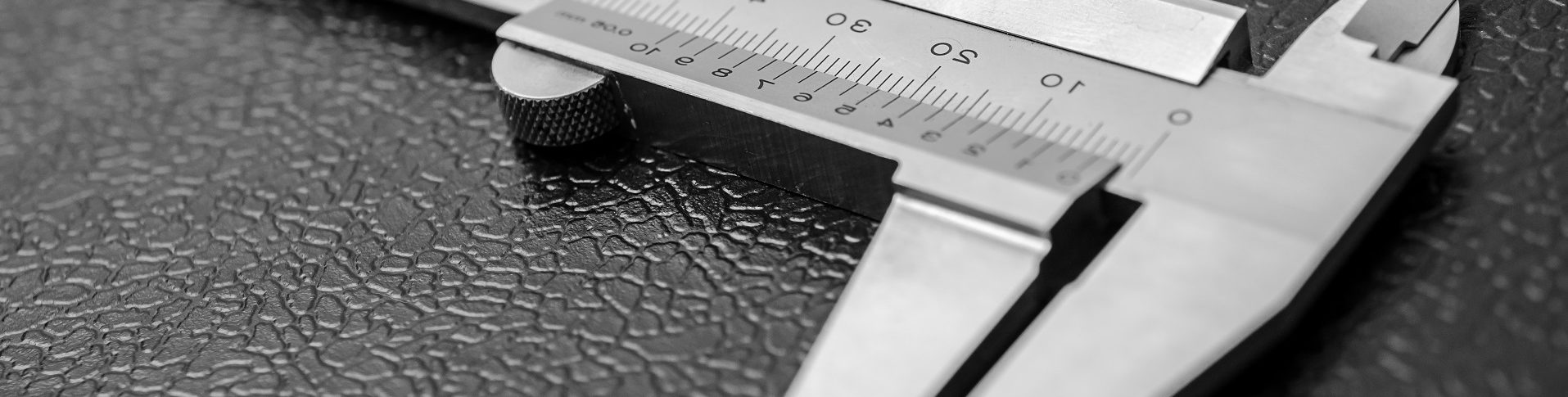

Calibration - measuring quality

Hanley Calibration entered the market 30 years ago to provide calibration support to the newly growing Irish pharmaceutical & medical device Industries. In doing so, Hanley’s partnered and helped develop the world class leading Calibration & Maintenance programs which now exist in the Biosciences Industries throughout Ireland.

Calibration compliance is integral to the life cycle of every piece of Instrumentation. Here at Hanley’s, we pride ourselves on executing industry compliant calibrations using our extensive range of Test Equipment.

Through in house training programs as well as fully audited & compliant procedures, our staff are trained in Calibration methods and the importance of Compliance from the beginning of their employment regardless of their experience. We achieve this through continuous assessment & appraisal while working with Hanley’s. We pride ourselves on being people-people whether it’s staff or customers we see the value in being human and developing relationships.

Trust is defined as “firm belief in the reliability, truth, or ability of someone or something”.

Here at Hanley’s, we pride ourselves on the trust of our customers. This has helped develop the type of contracts & services we now deliver today.